Glass deep processing types

Glass deep processing is mainly divided into the following categories

1. Tempered glass-Glass deep processing

The more commonly used glass deep-processing product is tempered glass. Whether it is a windshield or window glass for vehicles such as cars and trains, or a glass gate and partition for high-end hotels, tempered glass is used for glass tabletops and many glass curtain walls. This is because the strength of the tempered glass is 3 to 5 times that of the flat glass, and the resistance to quenching and heating is also better. And it is in the form of small particles after crushing, which will not cause great harm to people, so it is called safety glass.

The production of tempered glass is very simple. After cutting, chamfering, edging, polishing or punching, flat glass is cut into 650 ℃ The above tempering furnace is heated. And then quenched with cold wind to form a permanent compressive stress on the glass surface, which greatly improves the strength. This is tempered glass. Once the tempered glass is made, it cannot be cut and processed, otherwise it will be crushed.

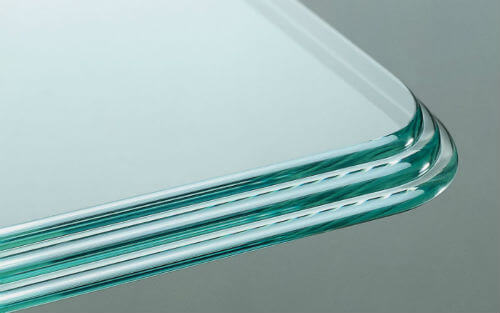

2. Laminated glass-Glass deep processing

Another type of safety glass is laminated glass. Its structure is like a “sandwich”, with transparent organic materials in the middle of the two layers of glass, firmly sticking the glass together. Therefore, even if the laminated glass is broken, there will be no debris splashing and hurting people. And the transparent interlayer film has good strength and toughness, and plays a good safety role. For example, in the event of a severe collision, the laminated windshield of the car can prevent the driver and passengers from being thrown from the windshield. And the soft organic material can also reduce the impact of the head of the person.

In addition, increasing the thickness and the number of layers of glass can make laminated glass have bulletproof, explosion-proof and anti-theft performance. And become a special glass for special windows. Of course, because the laminated glass also has a good sound insulation effect, effectively reduce noise (generally can reduce the noise 35 ~ 40 dB). So it is widely used in airport offices, waiting halls and other occasions that require sound insulation.

In the middle of the two pieces of glass, the isolation cabinet made of aluminum, and then glue them together. Forming a gap of 6 mm or 12 mm between the two pieces of glass, this is hollow glass. The insulating property of insulating glass is very good. The insulating property of 12 mm thick insulating glass is comparable to that of 100 mm thick concrete walls. Therefore, the glass curtain wall of the building and the relatively large glass windows should use hollow glass in order to reduce heating energy consumption.

Insulating glass also has good sound insulation. In addition to the use of flat glass as the original sheet for the manufacture of insulating glass, tempered glass, laminated glass, heat-reflective coating glass, heat-absorbing glass, etc. They can also be used as the original sheet to make advanced insulating glass with multiple functions for super high-rise buildings. The important parts such as the tourist office of things. In addition, the train’s air-conditioned cars and subway window glass are tempered hollow glass to improve thermal insulation, sound insulation and other properties.

3. Coated glass-Glass deep processing

Coated glass is also called reflective glass. Coated glass refers to coating one or more layers of metal, alloy or metal compound films on the glass surface to change the optical properties of the glass to meet certain specific requirements. According to different characteristics of products, coated glass can be divided into the following categories: heat reflective glass, low-e glass, Low-E, conductive film glass, etc.