HOW IS GLASS MADE: 6 STEP-BY-STEP PROCESS

1. Melting and Refining-HOW IS GLASS MADE

In order to make clear glass, the right set of raw materials is required. This consists of silica sand (SiO2), sodium oxide (Na2O) from soda ash, calcium oxide (CaO) from limestone/dolomite, dolomite (MgO), and feldspar (Al2O3). These ingredients are mixed in the right proportion, and the entire batch is flown into a furnace heated to 1500 degree Celsius.

In order to impart colour to the glass, certain metal oxides are also mixed in the batch.

2. Float bath-HOW IS GLASS MADE

The molten material from the furnace flows into the float bath which consists of a mirror-like surface made from molten tin. This material enters the bath at 1500 degree Celsius and leaves the bath at around 650 degree Celsius. Its shape at the exit is like a solid ribbon.

3. Coating for reflective glass-HOW IS GLASS MADE

Thereafter, if one is producing reflective glass surfaces that help in keeping indoors cooler, then coating procedures are followed in which either a hard coat or a soft coat is applied on the surface of the cooled ribbon at high temperatures.

4. Annealing-HOW IS GLASS MADE

Next, in order to remove the internal stresses built up in glass, a process called annealing is done. This process allows the glass ribbon to pass through a layer which eliminates any stresses on the glass surface and gradually cools it to give it its final hardened form. This makes it easier to cut the glass and shape it accordingly.

5. Inspecting-HOW IS GLASS MADE

Through acute and advanced inspection technology, more than a 100 million inspections can be made throughout the glass manufacturing procedure to identify air bubbles, stresses or grains of sand that refuse to melt. This is essential in quality-proofing the final form of glass.

6. Cutting to order-HOW IS GLASS MADE

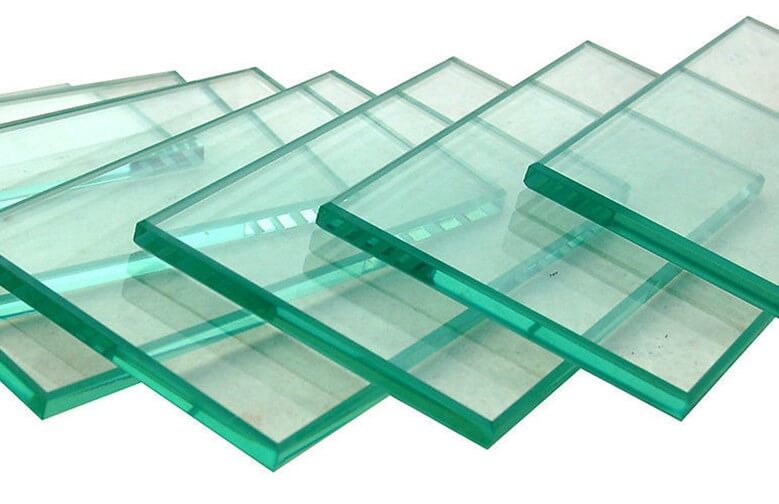

Finally, diamond steels are used to trim and cut the glass ribbons into square shapes.